SPREADING MACHINES ShuttleProgress through performance and precisionThe Kuris Shuttle spreading machine suits perfectly for critical, smooth materials and/or even badly rolled material bars with different surfaces. The new deviating roller system of the driven cradle or material bar ensures an excellent quality in spreading. Even through fully automatic spreading of tension-sensitive materials excellent spreading results will be achieved. The precise and regulated prefeed material roll will exactly suit the required spreading speed. The semi or fully automatic unthreading/threading of the fabric will reduce essentially the set-up times. Many steps to be taken for the spreading with different positioning and cutting points, quantity of layers, zig-zag spreading programmes as well as numerous custom-made parameters can be individually programmed. |

ADVANTAGES AT A GLANCE:

cradle with fully automated lifting for ergonomic loading process

a new idler-pulley system for the continuous running of the conveyor belt (option)

user-friendly machine control

graphical user interface

easy to use

software update possible even after several years of use

programming possibilities for many spreading steps

silicon coated drive wheel

photocell electric for the examination of the edge control even for difficult materials

different cutting units simply to be mounted

dynamic speed control

robust control cabinet-housing with powder coating surface

Options:

Fabric edge- blowing feature against curling effect

Turntable

Driven rolling bar for tension-free spreading

Zack-cutting unit

Zig-zag spreading with catcher system

Cradle execution (for fabric rolls up to 600 mm or up to 800 mm in diameter)

Travel-on platform and seating support

Anti-static bar

Loading equipment:

QUICK -LIFT

SPEED-LIFT

C350 LIFT

TECHNICAL DATA:

| Working widths: | 1,68 m / 1,83 m / 1,98 m / 2,13 m / 2,28 m | |

| Table widths: | up to 2.45 m (others on request) | |

| Spreading speed : | max. 100 m/min | |

| Spreading height: | 150 mm | |

| Fabric roll diameter: | max. 800 mm | |

| Fabric roll weight: | max. 125 kg | |

| Electrical connection: | 2,0 kW; 400 V | |

| Weight of machine: | depending on working width and equipment – from 500 kg | |

| Operation: | Touch panel with graphic interface |

Kuris, the specialist for innovative spreading and cutting technology. The comprehensive product range also allows solutions tailored to your particular needs. In our showroom, spreading and cutting machines are available both for general demonstrations and for testing with your own materials.

Arrange an appointment with us

We will be delighted to advise you!

Our areas of application

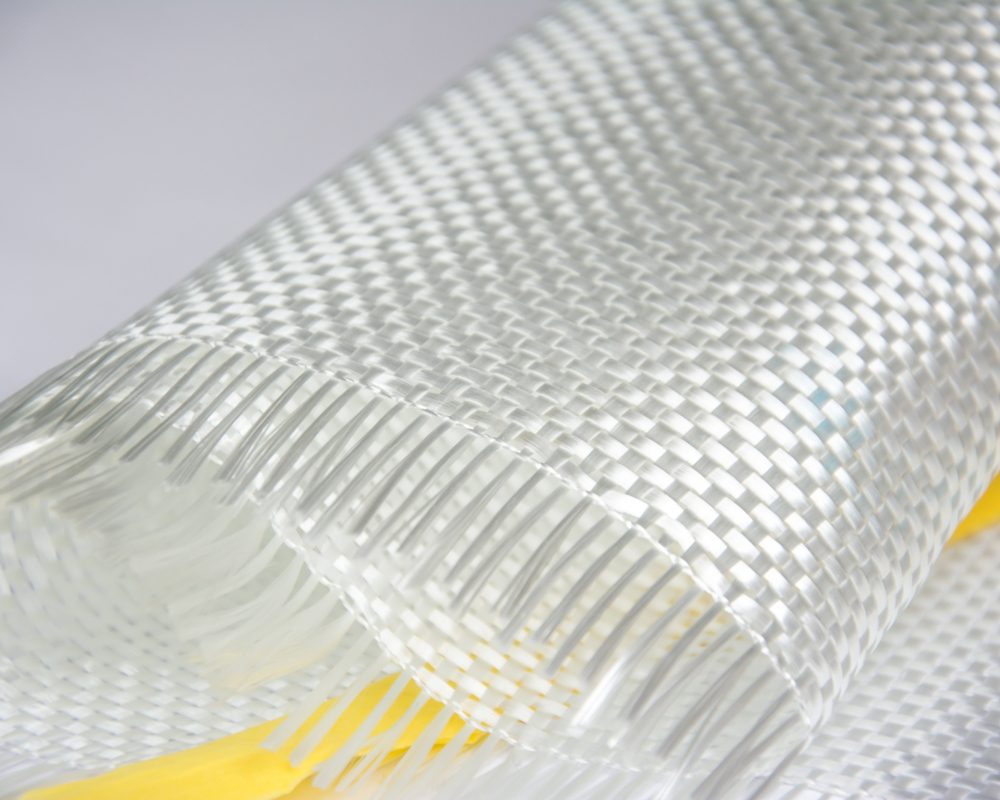

The areas of application of the systems from Kuris Spezialmaschinen GmbH include the automotive industry, the clothing industry, the furniture industry, technical textiles, aerospace engineering, shipbuilding, trains, construction industry and renewable energy like wind power or solar energy.

Automotive industry

Clothing industry

Furniture industry

Technical Textiles

Aerospace Engineering

Shipbuilding

Trains

Construction industry

Renewable Energy