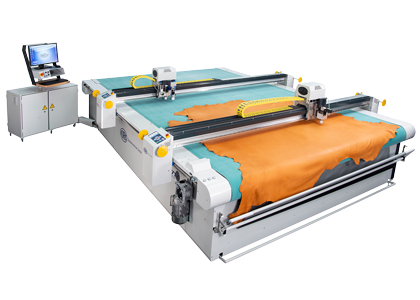

Single-ply LEATHER - PROFESSIONAL SOLUTIONS FOR THE COMPLETE PRODUCTION PROCESSLEATHER PROCESSING WITH KURISCompared with other industries and materials, leather cutting requires maximum attention and increased effort. This is why, in the leather industry in particular, the desire for a high degree of automation has always been present. We have set about doing this and have studied theentire production process in great depth. Our solutions have enabled us to really stand out in the leather market. Efficient and at a high level, topics such as smart order management, leather administration, leather scanning, powerful nesting and precise cutting are addressed. |

SPLIT WORK PROCESS

Splitting the overall process into several individual processes enables a high level of optimisation and efficiency. The leather hides are digitised with the scanner and assessed in the leather storage facility. The production order is created automatically via an interface with the ERP system. Large potential savings are guaranteed through the combination of orders and the targeted preselection of the leather hides and ultimately also through multi-hide nesting.

Nesting & Cutting

|

1. PRODUCTION PLAN Styles and patterns import and conversion, production quantity management, work distribution to one or several cutting stations 2. LEATHER SCANNING BY MEANS OF OPTICAL DEVICES Automatic detection of the leather contour, determination of quality zones on five levels with the aid of video projection, bar-code label printing, leather purchase report 3. INTELLIGENT ORDER MANAGEMENT Optimum matching of individual orders, article-based management 4. AUTOMATIC NESTING Automatic and interactive nesting directly on the leather, automatic quality zone matching, wireless mouse and keyboard that are easy to use, multi-hide nesting |

5. CUTTING Automatic cutting and marking using a variety of tools: oscillating knife, round knife, punch with different diameters, drills, pens 6. COLLECTING Interactive and swift part collecting procedure after cutting, using video projection, different collecting methods depending on the type of production 7. REPORTS Comprehensive reports on leather stock, cutting efficiency, consumption, mini-markers, production quantity reports |

IN-LINE SOLUTIONS

Optical devices such as cameras and projectors are used for acquisition and visualization. The OT1 Tool is a cutting tool perfectly matched to leather. The integrated cleaning brush guaranteed a reliable process for the optical devices. The service life of the cutting pad is also significantly extended.

|

1 ZONE (Compact solution) Compact configuration offering all features of a large system: leather scanning, automatic nesting, collecting and reports. All these operations are performed directly on the cutter table, in a very fast and efficient process. |

2 / 3 ZONEN (Series production) To increase the productivity, the system is expanded to include two more zones: 1. Leather scanning and nesting, 2. Cutting, 3. Collecting – These three steps are performed directly on the machine: a conveyor belt moves the leather from one stage to the next, in a continuous and economic workflow. |

OPTIONS

Drawing device

Drilling device

Milling device

Drag knife

Driven round knife

Oscillating knife

POT knifer

Printhead

TECHNICAL DATA (CUTTY 3527):

| Max. cutting height: | 40 mm (depending on tool) | |

| Max. cutting speed: | 70 m/min | |

| Max. positioning speed: | 100 m/min | |

| Max. acceleration: | 7 m/s² | |

| Nominal working widths (Y): | 1,75 m / 2,15 m / 2,75 m / 3,05 m | |

| Table widths: | 2,10 m / 2,50 m / 3,20 m / 3,50 m | |

| Nominal working lengths (X): | 2,30 m / 3,50 m | |

| Total lengths: | 3,80 m / 5,00 m | |

| Weight of the cutter: | 1950 kg / 2300 kg / 3800 kg | |

| Working height: | from 0,85 m | |

| Operating voltage: | 400 V, 50/60 Hz |

Connected electrical load

| Control / drives: | 4 kW | |

| Vacuum unit: | 7,5 kW / 11 kW | |

| Average consumption: | 8 kW | |

| Fuse: | 35 A (5x6mm²) | |

| Protection class: | Class 1 | |

| Compressed air (5-6 bar): | 10 l/min |

Noise level: 57 - 74 dB(A)

Certification mark: CE

The comprehensive product range also enables solutions for your needs. In our demonstration center, laying and cutting machines are available for general demonstrations as well as for test cuts with your own materials.

Make an appointment with us.

We are happy to help!

Our areas of application

The areas of application of the systems from Kuris Spezialmaschinen GmbH include the automotive industry, the clothing industry, the furniture industry, technical textiles, aerospace engineering, shipbuilding, trains, construction industry and renewable energy like wind power or solar energy.

Automotive industry

Clothing industry

Furniture industry

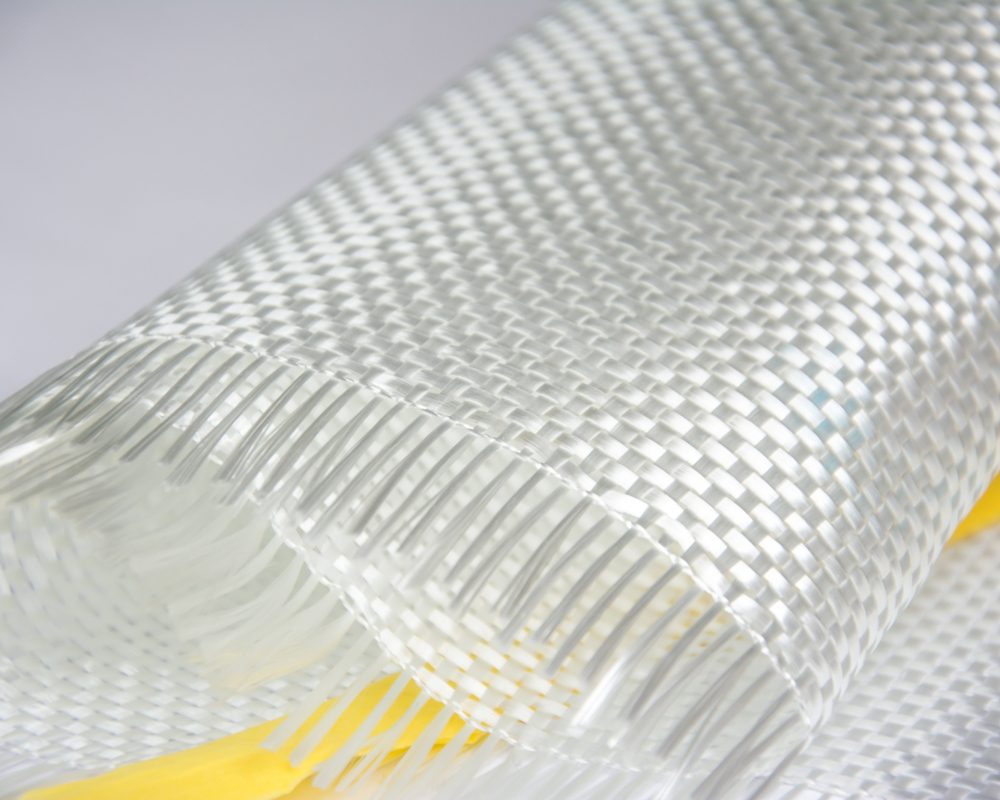

Technical Textiles

Aerospace Engineering

Shipbuilding

Trains

Construction industry

Renewable Energy