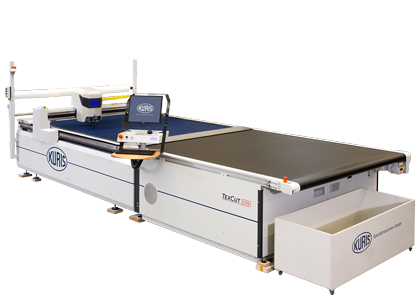

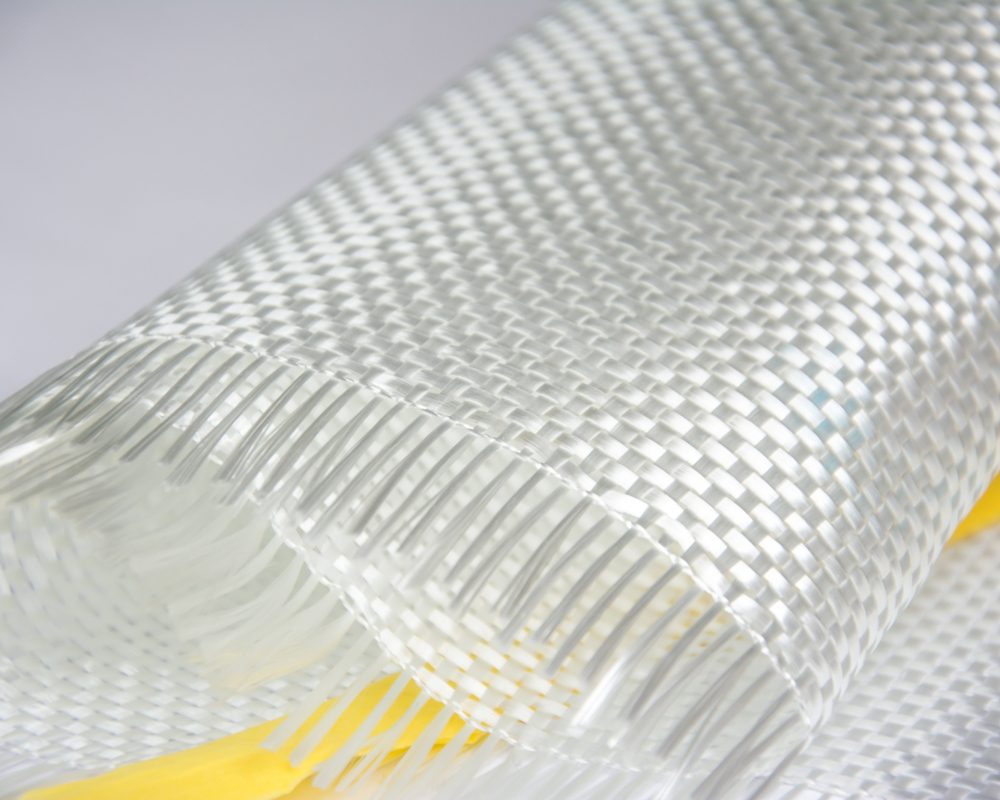

High ply cutters TexCut TC2219High-ply cutter for maximum cutting precisionFor cutting technical textiles and special materials such as foils and veneers, aramid, carbon and glass fibres prepregs and insulation material, sports and leisure products. For sample production and mass production in the clothing, furniture and automotive industries - and in many other branches of industry. In many areas of the manufacturing industry, the demands of an expanding global market lead to the innovation of existing processes. In many cases, this means shifting tasks that were previously done by hand to machines. This requires a machine technology which is powerful enough to increase the level of productivity already achieved, but at the same time is simple enough to pave the way for even beginners to embrace automatic cutting. Kuris has delivered this requirement with the TexCut series. |

BENEFITS:

Bristle belt with 2.2 m, 3.5 m or 4.5 m cutting window permits optimum adjustment to the size of the parts and cut files

Excellent cutting quality, also for cuts, difficult contours and hard materials due to automatic compensation of the knife bending (option: smart knife)

High cutting speed guarantees highly effective output even for single plies

Reduced energy consumption thanks to economic vacuum unit, vacuum output is optimally controllable (option)

Easy to operate thanks to fully developed operator guidance

Easy to service thanks to standardised components, low-maintenance

Fast and straightforward change of knife and cutting head thanks to patented service position

Automatic parallelism monitoring – no subsequent manual alignment of the layer package

Automatic plausibility check – prevents faulty cuts if an operating error occurs

Resealer for a better vacuum (option)

TECHNICAL DATA:

| Max. cutting height: | Up to 100 mm compressed | |

| Max. cutting speed: | 90 m/min | |

| Max. positioning speed: | 120 m/min | |

| Working widths: | 1,90 / 2,20 / 2,40 m (others available on request) | |

| Overall width of the cutter frame: | 2,25 / 2,55 / 2,75 m | |

| Total length of the cutter frame: | 3,20 / 4,50 / 5,50 m | |

| Effective cutting length: | 2,20 / 3,50 / 4,50 m | |

| Length of the clearing area: | 2,00 / 2,50 / 3,30 / 4,30 m | |

| Total width of the clearing belt: | 2,10 / 2,40 / 2,60 m | |

| Total length of the cutter system: | 5,20 / 5,70 / 7,80 / 9,80 m | |

| Weight of the cutter unit: | approx. 3600 - 3900 kg | |

| Weight of the vacuum unit: | approx. 100 - 800 kg |

Connected electrical load:

| Operating voltage: | 230 / 400 V, 50 / 60 Hz, 3-Phasen | |

| Cutter including clearing belt: | 4 kW | |

| Economic vacuum unit: | 18,5 - 30 kW | |

| Compressed air (5-6 bar): | 10 l/min | |

| (for drilling device): | 230 l/min (temporarily) | |

| Protection class: | Class 1 |

|

Options:

|

Knife sizes:

|

Our knives are available with different coatings. The blades are optionally available with a serrated or sawtooth cut and are made of HSS or hard metal.

Acoustic level: 57 - 74 dB(A)

Mark of conformity: CE

TC2219

Downloads

You can find further information and technical details

in our brochures.

Kuris, the specialist in innovative spreading and cutting technology. Our product range offers solutions for various individual requirements. Our showrrom offers the possibility for demonstrations and cutting tests with your individual materials.

For further information about our products, please send us your enquiry.

We would be pleased to give you an individual consultation.

Our areas of application

The areas of application of the systems from Kuris Spezialmaschinen GmbH include the automotive industry, the clothing industry, the furniture industry, technical textiles, aerospace engineering, shipbuilding, trains, construction industry and renewable energy like wind power or solar energy.

Automotive industry

Clothing industry

Furniture industry

Technical Textiles

Aerospace Engineering

Shipbuilding

Trains

Construction industry

Renewable Energy