MANUAL CUTTING MACHINES

MANUAL CUTTING MACHINES WITH POWER AND ENDURANCE FOR INDUSTRY AND HANDCRAFT

Innovative products in HIGH-TECH QUALITY

It is difficult to imagine cutting and spreading without Kuris handheld cutting machines. The machine has to cater for the operator’s method of working and not the other way round!

All machines are VDE-tested!

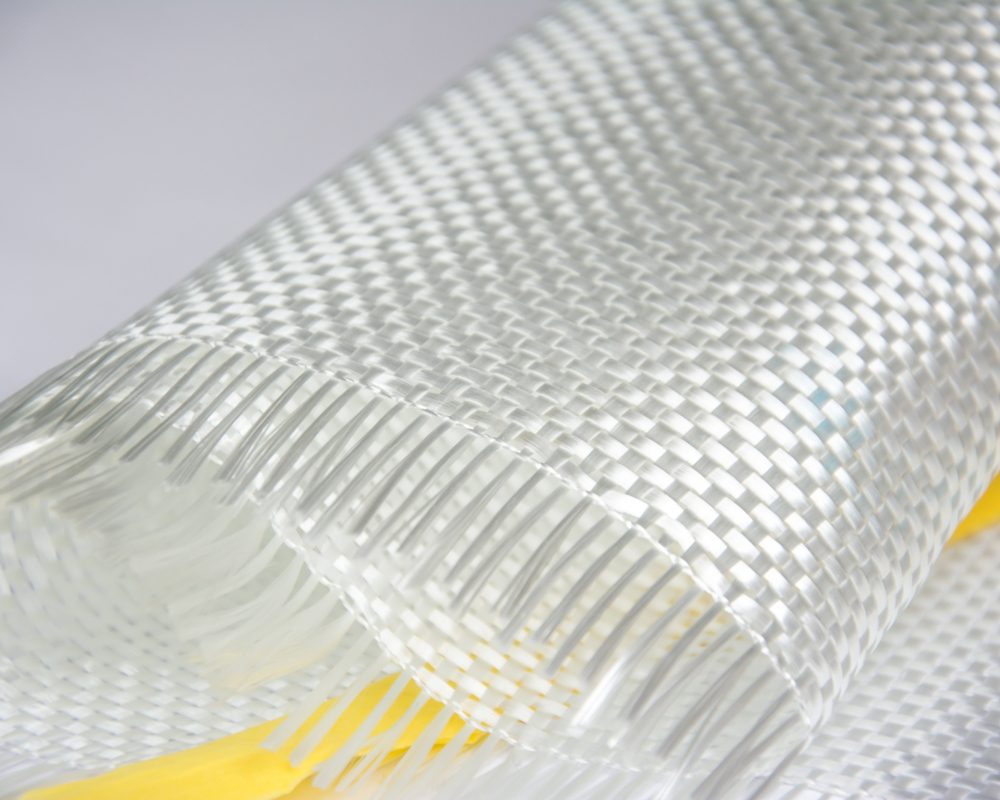

MANUAL CUTTING MACHINESThe step to a better cut Make the step towards a better cut Fit in the cutting industry starts with accurately cut material or technical textiles. Seldom has a handheld cutting tool been so keenly tailored to the cutter. Cutting thick layers, into tight corners, at acute angles - this is precisley what the machines are designed for. The quality of the cut - that is decided by the cutter and the cutting blade. Kuris‘ new small cutting machines glide easily through the fabric; they produce a cleaner cut and are more manageable. Today, rotating blade machines are used primarily for straight, long cross cuts. Thanks to the smooth, clean cut they are excellently suited to knitted goods and knitwear as well as linings and other materials that are susceptible to fraying and the build-up of fluff. There are also various applications in the manufacture of upholstered furniture and mattresses (cutting upholstery and diol fabrics etc.) in felt, cotton wool and dressing material, blanket, carpet and bodywork factories. The rotating blade gets its cutting effect in combination with the jaw with knife-edged joints fitted to the base plate. The integrated grinding device resharpes the blade. Steel blades with a higher service life can be supplied for extreme loads. The finger guard provides saftey when cutting and offers protection against injuries. The drive motors can be designed for DC and AC current. If required, Kuris rotating blade machines can be fitted with a four-arc knife and counter blade for cutting plastic material and rubber etc. The special half-speed or multiple speed motor is then recommended. The machine can then be fitted with a blade damping device to prevent the knife from becoming encrusted with cutting residues. |

STRAIGHT-KNIFE CLOTH CUTTERSSharp, quick, convenient application. Easy and reliable to operate. Kuris straight-knife cloth cutters with cutting heights of 70 to 210 mm are ideal tools for all cutting operations. From pattern- making through to cutting multiple layers, they are suitable for all flexible surface structures, such as textiles, knitwear and knitted goods, technical textiles and special materials, such as films, felt, Skai, branded films and soft leather etc. The machines excel in being able to keep to the curves. Thanks to its particularly narrow and low construction, the machine provides good visibility of the blade. A special coating offers excellent glide properties and considerable wear resistance. Sliding handle, carrying handle, presser handle, ON / OFF switch and sharpening tool activation are optimally configured. The machines are carefully balanced and easy to manage. Whoever works with them feels they are an extension to themselves. The blade is sharpened on both sides as it is lifted up and down. Unusually even and exact. The layers of material are therefore always cut cleanly, free from fraying right down to the bottom layer of material. An important feature (especially with the KVS 900) is, that it is not possible for the grinding equipment drive to be damaged when the grinding attachment comes up against an obstacle (e.g. layer of material). WHO NEEDS THESE STRONG AND FLEXIBLE MACHINES?Ladies, gentlemen and childrens‘ clothing, sports and professional clothing factories, linen, knitwear and hosiery production, stocking makers, bed linen, bed and quilt makers, curtain and home dècor material production and the entire home decoration sector, upholstered furniture industry, saddlers, tanneries, leather manufactures, glove manufactures, hat and bonnet production, toys and dolls‘ clothes manufacture. Workshop of public authorities, hospitals, weaving mills, home textilies, tie manufactures, handcraft industry, slipcover manufacturers, dockyard and ship rigging, carpet factories, large book binders, fibre glass processing companies, woven felt factories, automotive, shoe-makers, pushchair manufacturers, manufacturers of camping articles, caravan manufacturers, fur processors, paper board factories, office furniture manufacturers and fisheries. |

Several advantages at a glance:

Excellent handling

Lower cutting resistance

Lower power requirement

Better around curves

Higher cutting speed

Novita StandardEffortlessly clean and without considerable technical investment you are therefore able to cut all manner of textiles and soft leather. There are applications for single layer and multiple layer cutting, particularly for cutting templates and patterns. Also ideal for trimming defective parts, for cutting knitwear and knitted goods straight and curtains, upholstery and decorative fabrics true to form, even for an unconventional application. Icelandic fishermen separate the tail fins of plaice and other fish, using the Novita Standard. The lubricator decreases friction between the blade and counter blade, enabling laminated goods to be cut. The Novita Standard is fully insulated and VDE tested. A special combination gear mechanism gives the machine a unique motor speed strength across the entire load range. The motor only gets moderately warm, preventing overload and guaranteeing the highest protection and service life. The blade guard is easily and infinitely adjustable and does not obscure blade visibility. The operating handle for the grinding device has been shaped in such a way, that the blade can be sharpened using one hand, even during the cutting operation. Handling and management of the machine is easy and balanced. |

TECHNICAL DATA

| Motor power: | approx. 56 Watt | |

| Motor data: | 220 V / 50 Hz | |

| Operating time: | 60 % (no non-stop operating) | |

| Motor speed (idle): | approx. 11.000 U/min | |

| Blade speed (idle): | approx. 2.600 U/min | |

| Blade diameter: | 50 mm | |

| Blade wear limit: | approx. 42 mm | |

| Cutting height: | 8 mm | |

| Motor diameter: | approx. 50 mm | |

| Machine length: | approx. 230 mm | |

| Machine weight, excl. cable: | approx. 850 g | |

| Vibration: | < 2,5 m/s | |

| Running noise: | 73 dB(A) |

There is the option of three bases, depending on the application:

33283 – Novita Standard with flat base

33284 – Novita Standard with skid base

33289 – Novita Standard with skid base with protective ball

NOVITA SuperThe „Novita Super“provides concentrated force to withstand heavy and even the most difficult of loads. The cutting performance is 10x greater than that of the Novita Standard version. Particularly handy and lightweight machine for cutting all types of material in layers up to approx. 8 mm high, depending on the material. Particularly suitable for needled felt, Skai, branded films, soft leather and upholstery cover materials. The lubricator reduces friction between the blade and the counter blade, enabling laminated goods to be cut. Cutting machine for template and pattern making, cutting single layers, re-cutting defectives parts, straight cutting true to form, light load (outer wear materials, knitted goods and knitwear, curtain, upholstery and decoration fabrics etc.). The blade protection in signal colour can be adjusted easily and infinitely and does not constrict the visibility. The actuating lever for the grinding device is well shaped, so that the blade can be re-sharpened with one hand even during cutting. Handling and guidance of the machine is easy and balanced. |

TECHNICAL DATA

| Motor power: | approx. 56 Watt | |

| Motor data: | 220 V / 50 Hz | |

| Operating time: | 60 % (no non-stop operating) | |

| Motor speed (idle): | approx. 12.500 U/min | |

| Blade speed (idle): | approx. 1.500 U/min | |

| Blade diameter: | 50 mm | |

| Blade wear limit: | approx. 42 mm | |

| Cutting height: | 8 mm | |

| Motor diameter: | approx. 50 mm | |

| Machine length: | approx. 260 mm | |

| Machine weight, excl. cable: | approx. 850 g | |

| Vibration: | < 2,5 m/s | |

| Running noise: | 73 dB(A) |

NOVITA PlusA particularly convenient and lightweight machine for cutting all kinds of textiles for layers and up to approx. 8 mm high, depending on the type of material. Especially suitable for wool and soft materials. Either the flat base or the cutting skid may be used. The lubricator decreases friction between the blade and counter blade, enabling laminated goods to be cut. The Novita Plus is fully insulated and VDE tested. A special combination gear mechanism gives the machine a unique motor speed strength across the entire load range. The motor only gets moderately warm, preventing overload and guaranteeing the highest protection and service life. The blade guard is easily and infinitely adjustable and does not obscure blade visibility. The operating handle for the grinding device has been shaped in such a way, that the blade can be sharpened using one hand, even during the cutting operation. Handling and management of the machine is easy and balanced. |

TECHNICAL DATA

| Motor power: | approx. 56 Watt | |

| Motor data: | 220 V / 50 Hz | |

| Operating time: | 60 % (no non-stop operating) | |

| Motor speed (idle): | approx. 12.400 U/min | |

| Blade speed (idle): | approx. 3.000 U/min | |

| Blade diameter: | 50 mm | |

| Blade wear limit: | approx. 42 mm | |

| Cutting height: | 8 mm | |

| Motor diameter: | approx. 50 mm | |

| Machine length: | approx. 260 mm | |

| Machine weight, excl. cable: | approx. 850 g | |

| Vibration: | < 2,5 m/s | |

| Running noise: | 73 dB(A) |

NOVITA JetThe Novita Jet is a modified version of the compressed air operated Novita Standard. It provides ease of use and increased performance everywhere where no electrical connection is possible for saftey reasons, e.g. in wet areas. Untiring and reliable just like all Kuris‘ NOVITA cutting machines. The Novita Jet is driven by compressed air. Therefore every saftey risk is eliminated (overload and the electric motor burn out). The motor cannot overheat even at a constant output and capacity overload. The outlet air is evacuated to the rear through a double-walled tube - inner tube for supply air; outer tube for discharged air and released into the atmosphere far away from where the cutter is working. It therefore no longer presents a disruption to anyone, either as a result of draughts (air swirls, cold effect, circulating fluff) or even by whistling. The lubricator reduces friction between the blade and the counter blade, enabling laminated materials to be cut. |

TECHNICAL DATA

| Motor power: | approx. 0,15 kW | |

| Blade speed (idle): | approx. 1.900 U/min | |

| Operating pressure: | 6 bar (max) | |

| Tube width, clearance: | 6 mm | |

| Air consumption at nominal load: | 0,25 Nm3/min | |

| Cutting height, max.: | 8 mm | |

| Housing diameter: | 38 mm | |

| Machine length: | approx. 220 mm | |

| Machine weight, excl. tube: | approx. 0,9 kg |

BOM 30A particularly convenient and lightweight machine for cutting all kinds of textiles for layers up to approx. 25 mm high, depending on the type of material. Especially suitable for wool and soft materials. The lubricator reduces friction between the blade and the counter blade, enabling laminated goods to be cut. For universal use for cutting single and multiple layers, light to medium load (traditional clothing materials, such as knitted goods, knitwear and decorative fabrics etc.). Also available with an extension (also with automatic ON/OFF switch) and special base for aluminium track for trimming endless fabric. |

Benefits:

With the BOM 30 series of electric handheld cutters, the cutting effect is produced by a six-arc blade in conjunction with a sprung-loaded adjacent counter blade. This cutting principle enables good cutting performance at relatively low blade speeds. Individual layers of the finest materials and layers of material up to a cutting hight of 25 mm can be cut equally well. High traction force thanks to a robust motor with a high power margin. Optimal blade propulsion across synchronous belts and cylindrical gears with excellent operating efficiency. Practically maintenance- free thanks to a special seal. Highest performance and service life due to very low heat generation in the motor and gears.

Sturdy reliability thanks to the sprung-loaded counter blade. With carbide counter blade and HSS blade for heavy materials on request. Every machine possesses an adjustable finger guard based on employers‘ liability insurance regulations. Not susceptible to contaminants, threads and fluff thanks to the special development and construction of the support and gear mechanism housing.

TECHNICAL DATA

| Motor power: | approx. 140 Watt | |

| Motor data: | 230 V / 50 Hz | |

| Motor speed (idle): | approx. 8.000 U/min | |

| Blade speed (idle): | approx. 1.000 U/min | |

| Blade diameter: | 80 mm | |

| Blade wear limit: | approx. 72 mm | |

| Cutting height, max.: | approx. 25 mm | |

| Vibration: | 2,5 m/s | |

| Running noise: | 73 dB(A) | |

| Machine weight, excl. cable: | 2,2 kg without cable |

The BOM 30 SK and BOM 30 SL versions are supplied with a special base that is fed into an aluminium profile track. The BOM 30 SL with the extension and automatic ON/OFF switch is particularly suitable for trimming endless fabric.

BOM 101A particularly convenient and lightweight machine for cutting all kinds of textiles for layers up to approx. 25 mm high, depending on the type of material. The fortified „Power" versions particularly suitable for jeans, leather and rigid fabrics as well as industrial fabrics. The lubricator reduces friction between the blade and counter blade, enabling laminated goods to be cut. |

Benefits::

With the BOM 101 series of electric handheld cutters, the cutting effect is produced by a four-arc or six-arc blade in conjunction with a sprung-loaded adjacent counter blade. This cutting principle enables good cutting performance at relatively low blade speeds. Individual layers of the finest materials and layers of material up to a cutting hight of 27 mm can be cut equally well. High traction force thanks to a robust motor with a high power margin. Optimal gear mechanism made from a special alloy with excellent operating efficiency and simple maintenance. Practically maintenance-free thanks to a special seal. Highest performance and service life due to very low heat generation in the motor and gears.

Not susceptible to contaminants, threads and fluff thanks to the special development and construction of the support and gear mechanism housing.

Light handling and handy machine controls in all cutting positions thanks to the „bone grip“. Grinding device very easy to operate thanks to the ideal configuration of the operating element. Optimal view of the workpiece thanks to the oval shape of the housing. Very low running noise. Quick blade change thanks to easy and very accessible blade fixing.

TECHNICAL DATA

| Motor power: | approx. 140 Watt | |

| Motor data: | 230 V / 50 Hz | |

| Motor speed (idle): | approx. 8.000 U/min | |

| Blade speed (idle): | approx. 1.000 U/min | |

| Blade diameter: | 80 mm | |

| Blade wear limit: | approx. 72 mm | |

| Cutting height, max.: | approx. 27 mm | |

| Vibration: | 2,5 m/s | |

| Running noise: | 73 dB(A) | |

| Machine weight, excl. cable: | 2,2 kg |

The BOM 101 SK and BOM 101 SL versions are supplied with a special base that is fed into an aluminium profile track. The BOM 101 SL with the extension and automatic ON/OFF switch is particulary suitable for trimming endless fabric.

BOM 101 AKKUA particularly convenient and lightweight machine for cutting all kinds of textiles for layers up to approx. 27 mm high, depending on the type of material. The lubricator reduces friction between the blade and the counter blade, enabling laminated goods to be cut. |

Benefits:

With the BOM 1010 series of electric handheld cutters, the cutting effect is produced by a four-arc or six-arc blade in conjunction with a sprung-loaded adjacent counter blade. This cutting principle enables good cutting performance at relatively low blade speeds. Individual layers of the finest materials and layers of material up to a cutting hight of 27 mm can be cut equally well. High traction force thanks to a robust motor with a high power margin. Optimal gear mechanism made from a special alloy with excellent operating efficiency and simple maintenance. Practically maintenance-free thanks to a special seal. Highest performance and service life due to very low heat generation in the motor and gears.

Not susceptible to contaminants, threads and fluff thanks to the special development and construction of the support and gear mechanism housing.

Light handling and handy machine controls in all cutting positions thanks to the „bone grip“. Grinding device very easy to operate thanks to the ideal configuration of the operating element. Optimal view of the workpiece thanks to the oval shape of the housing. Very low running noise. Quick blade change thanks to easy and very accessible blade fixing.

The advantage of BOM 101 Akku in relation to BOM 101 series is the independence through the battery.

TECHNICAL DATA

| motor power: | approx. 140 Watt | |

| Motor data: | 12 V | |

| Motor speed (idle): | approx. 11.000 U/min | |

| Blade speed (idle): | approx. 900 U/min | |

| Blade diameter: | 80 mm | |

| Blade wear limit: | approx. 72 mm | |

| Cutting height, max.: | approx. 27 mm | |

| Vibration: | 2,5 m/s | |

| Running noise: | 62 dB(A) | |

| Machine weight: | 1,75 kg without battery / gross 5,0 kg |

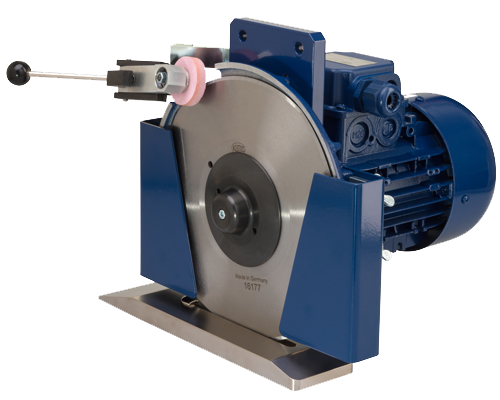

KRS 550The KRS 550 model of the Kuris cutting machines can be supplied as a rotating blade or a four-arc machine with counter blade. It is possible to convert a rotating blade machine to a four-arc blade machine or vice versa using an appropriate unit. KRS 550 with rotating blade 1. For cutting all kinds and designs of textile materials. 2. Particularly suitable for cutting knitwear and knitted goods and quilted materials that tend to fray easily or produce fluff. KRS 550 with four-arc blade and counter blade, for cutting 1. Synthetic material that tend to be over a certain height for bonding cut edges. 2. Plastic materials (Skai, branded films, etc.). 3. Laminated flooring. 4. Synthetic rubber interwoven materials (also rubber or soft rubber up to a certain height). The KRS 550 can be fitted with a blade damping device to prevent the blade from becoming encrusted with cutting residues. A teflon-coated blade is recommended for cutting particularly critical material. |

TECHNICAL DATA

| Cutting height, max: | 55 mm | |

| Blade diameter: | 120 mm | |

| Blade wear limit: | approx. 93 mm | |

| Running noise: | <70 dB(A) | |

| Machine weight: | 10,5 kg |

KSM 200L Q L/REdge and middle cutters for special applications, individual customer solutions or special machine construction. KSM 200 in left-hand and right-hand design The KSM 200 machines have a rotating blade made from tool steel, a grinding device with two sharpening edges and no base plate. We recommend the rotating blade in HSS quality for certain types of cut. You can distinguish between left and right by looking at the machine from the side of the blade. If the grinding device is located on the left, this is a left-hand version. If the grinding device is located right, this is a right-hand version. KSM 200 L in left-hand and right-hand version The „L“ stands for lengthways cutter. Even this machine is constructed in a left- and right-hand version, i.e. for use as a pair for trimming endless fabric etc. The KSM 200 L possesses an HSS quality four-arc blade, a co-ordinated unilateral grinding device and a base plate with counter blade, i.e. it can only cut in one direction. KSM 200L Q The „Q“ stands for cross cutter. This machine also has an HSS quality four-arc blade, unilateral grinding device and, in contrast to the KSM 200 L model, a base plate with two counter blades, enabling the KSM 200 Q model to cut in both directions. |

TECHNICAL DATA

| Motor power: | 0,37 kW | |

| Cutting height, max.: | 22 mm with protection 40 mm without protection |

|

| Blade diameter: | 200 mm | |

| Weight: | 9,5 kg |

KVS 700The ideal machine for all cutting operations, from pattern making to cutting multiple layers, with maximum cutting heights of 8 to 210 mm, for flexible surface structures such as textile fabrics, knitted goods and knitwear, technical textiles and special materials such as films, felt, Skai branded films and soft leather etc. The KVS 700 straight-knife cloth cutter bridges the former gap between electric handheld cutting machines and conventional straight-knife cloth cutters for thick layers. An electric handheld cutting machine with rotating blade will have problems cutting acute angles and tight curves at certain layer heights. In contrast, even darts, necklines and similar can be cut out using a single-knife cloth cutter. The base plates for the Kuris straight-knife cloth cutters are provided with a special coating. This offers excellent glide properties and high wear resistance. |

Benefits:

The good cutting performance is the result of the high stroke rate of the blade, the tips of which only project a little way from the base plate, making it possible to achieve a clean cut for a smaller number of layers. The grinding equipment is semi-automatic, i.e. the two grinding discs are power driven and the grinding device is lifted by hand. The blade driving mechanism and guide have been optimized. All the rotation parts run on ball bearings. The machine is therefore virtually maintenance-free.

TECHNICAL DATA

| Motor data: | 220-250 V WS 50/60 Hz | |

| Max. cutting height: | approx. 70 mm | |

| Motor power: | approx. 140 Watt | |

| Blade stroke: | 12-15-18 mm | |

| Weight: | 6 kg |

KVS 900The KVS 900 straight-knife cloth cutter is the machine for the job. Ideally suited to cutting every type and design of textile material, though particularly for cutting thick layers, tight curves and acute angles. Straight-knife cloth cutter for average layer heights, even for difficult to cut materials, high cutting accuracy thanks to the very small dimensions of the base plate, support and blade, fatigue-proof work with quiet running, good overview and low weight. We play it safe when it comes to safety. Just like all Kuris models, the Kuris KVS 900 meets the relevant safety standards. Possible sources of danger are already ruled out at the design stage. Therefore the presser foot bar with only a 13 mm gap from the blade takes on an additional function as a blade guard. An important feature (especially with the KVS 900) is that it is not possible for the grinding device drive to be damaged when the grinding device comes up against an obstacle (e.g. a layer of material). The very high lifting speed of the grinding head at approx. 1 s per sharpening operation reduces sharpening times quite considerably, making it possible for the grinding wheel to reach an optimum of 7 rpm. The blade is sharpened on both sides as it is lifted up and down. Unusually even and exact. The layers of material are therefore always cleanly cut, free from fraying right down to the bottom layer of material. |

Benefits:

Exact, sharp cut thanks to the automatic grinding device with whetstones

Sturdy special motor with a high power margin

Narrow supports reduce effort

Low base plate with a special surface minimizes slide resistance

TECHNICAL DATA

| Motor power: | 0,37 kW | |

| Max. cutting height: | approx. 90 mm | |

| Motor speed (idle): | 2.800 rpm | |

| Blade stroke: | 36 mm | |

| Vibration: | 2,5 m/s | |

| Weight: | approx. 8,4 kg | |

| Running noise: | 70 dB(A) |

KV 1602 / 2002 E/UVVThe straight-knife cloth cutter is suitable for cutting every type and design of textile materials, though especially for cutting thick layers, tight curves and acute angles, right up to the heaviest loads of all kinds of clothing materials and practically every industrial fabric etc |

Benefits:

The machine has an automatic grinding device and is largely maintenance-free. The machine is easy to move.

Exact, sharp cut thanks tot he automatic grinding device with sanding belts

Sturdy special motors with a high power margin

Narrow support for reducing effort

Low base plate with a special surface for minimizing slide resistance

Machine and blade guard equipment to CE and accident prevention regulations

Made in Germany

TECHNICAL DATA

| Motor power: | 0,75 kW | |

| Max. cutting height: | 1602 = 160 mm / 2002 = 200 mm | |

| Motor speed (idle): | 2.800 U/min | |

| Blade stroke: | 40 mm | |

| Weight: | 15 kg |

Manual cutting machines

Downloads

You can find further information and technical details

in our brochures.

KURIS manual cutting Machines

Our areas of application

The areas of application of the systems from Kuris Spezialmaschinen GmbH include the automotive industry, the clothing industry, the furniture industry, technical textiles, aerospace engineering, shipbuilding, trains, construction industry and renewable energy like wind power or solar energy.

Automotive industry

Clothing industry

Furniture industry

Technical Textiles

Aerospace Engineering

Shipbuilding

Trains

Construction industry

Renewable Energy